1.

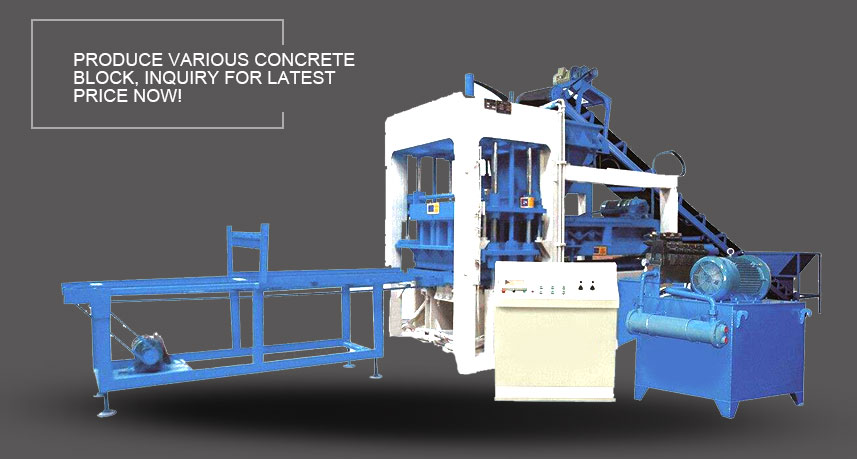

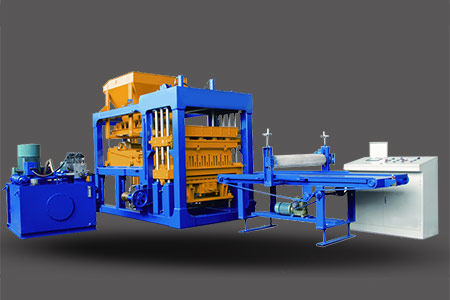

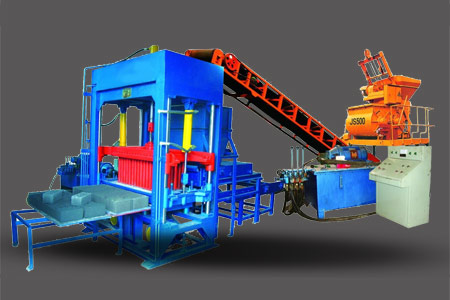

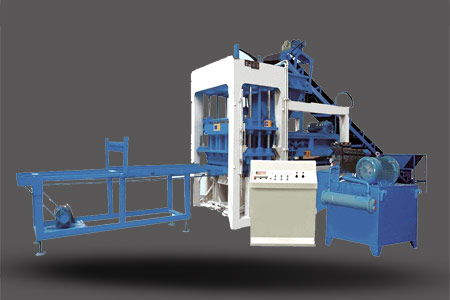

Main body frame: apply high-duty structural steel and Special welding technic, its outstanding steadiness will guarantee the equipment’s rigidity and seismic resistance.

2.

Guidepost: apply with super special steel, chromeplated surface will give good torsion resistance and wear-resisting performance, plus Four rod guide mode and over-length type guide bearing, which guarantees the accurate move of indenter and molds; moving parts apply special device, in order to easy lubricate and not easy wear.

3.

Color system: The color device crane apply hydraulic system control, by connection of rubber spring and crane the color device and hopper vibrating will be damped, in the meantime, it can prevent the left color concreted, discharge gate control the hopper, in order to achieve evenly color distributing.

4.

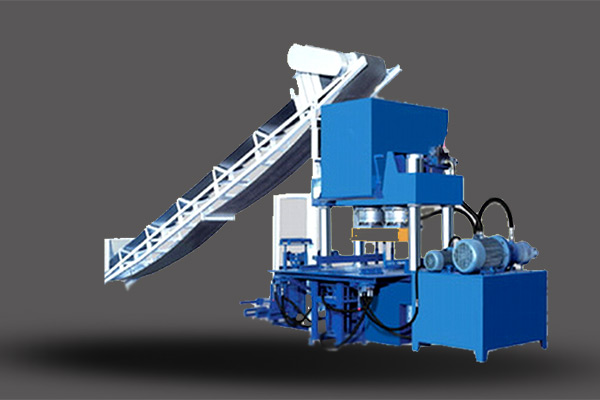

Distribution system: apply design of material storage and material separate dividing tech. material box feeding can be precisely controlled, under the effect of enforcing broken arch machine, which generate strong centrifugal discharging force, to make material distributing fast and even.

5.

Vibration system: Separate coupling vibration technology is used to expand the effective vibration area by 2 times, which greatly improve the quality and output of the production, and effectively extend the life of the mold; The vibration box adopts a suspended structure and can withstand severe vibration without damage. And the vibrating shaft adopts the eccentric synchronous rotation structure to generate the excitation force in the vertical direction, which can optimize the fabric and the forming effect.

6.

PLC control system: set the technical parameters such as flow and pressure of each action through the touch screen to achieve ideal man-machine dialogue. The control system consists of three control units: batch mixing automatic program control system, molding host, transport board machine, lift-unload automatic program control system and weight control system. The electrical components of this system are all imported brand products, such as Mitsubishi, Omron, Siemens, etc, thus ensure reliable performance and low failure rate.

7.

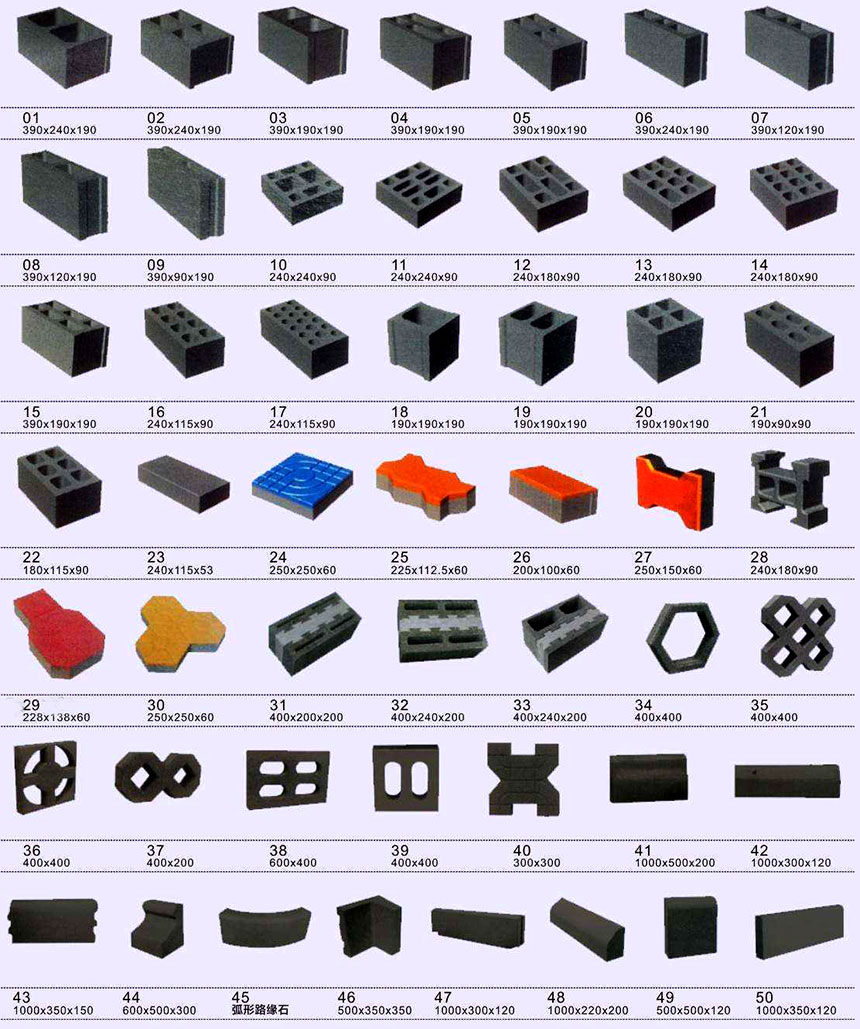

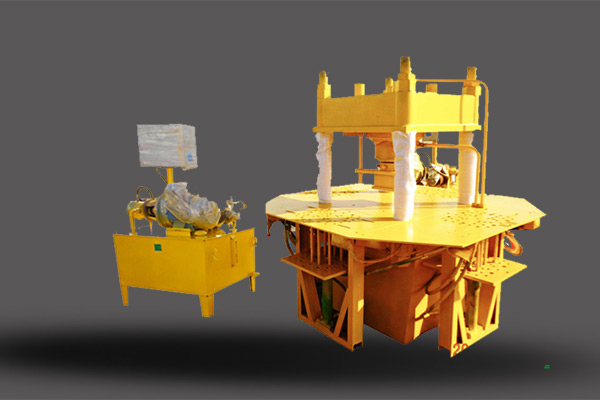

Multi-purpose of one machine: By replacing the mold, it can produce cement products with different specifications of porous bricks, hollow blocks, roadside stones, pavement bricks, grass bricks and slope protection bricks. The fabric device can produce products such as colorful pavers.

Tags:

pavers machine in Sanbaoyan brick making machine price suppliers in Sanbaoyan soil brick making machine manufacturers in Sanbaoyan

1 bag concrete mixer in Palanakconcrete mixer machine with lift price in Makaticoncrete transit mixer for sale in General of SantosMalaysia concrete batching plant in Laplace