Product classification

CONTACT US

WECHAT/WHATSAPP :

Skype :

TEL :

0086-371-86525099

0086-15136236223

E-MAIL :

Concrete Block Making Plant

● Products :QT4-15B Block Making Plant

● Type :Concrete Block Making Plant

● Brand :HAMAC

● Origin :China

If you want to know more details, please contact us, we will reply you as soon as possible.

>

Product Introduction>

Benefits & Features>

More Info

1. QT4-15B Automatic block forming machine Main technical parameters:

| forming machine theoretical data | |||

| Dimension of host machine | 2.44x2x2.6 m | Mixer style | JS500 / JD500 |

| main vibrator style | lower mould vibration | Number of hydraulic vibrator | 0 |

| control style | PLC | forming style | hydraulic |

| Number of motor vibrator | 4 | hydraulic cylinders | 1 |

| Hopper capacity of concrete | 0.6 M3 | feeding style | 360degree revole |

| Moulding area | 800x400 mm | forming height | 40-250mm |

| Moulding period | 15-20 S | vibration force | 42 kn |

| forming blocks per mould 400x200x200mm | 4 | The size of the pallet | 1010x550 mm |

| Weight of the host machine | 15T | ||

| Water and Voltage | |||

| Genetal water Consumption | 5.5T | Voltage | 380 V |

| Power | 27 kw | . | . |

|

Simple line Uesd Area |

|||

| A.Production area excluding concrete mixing zone | M2 | 400 | |

| B. Concrete mixing zone area | M2 | 100 | |

| C.Finished product Warehouse | M2 | 600 | |

| E.Raw material storage | M2 | 500 | |

| F.office | M2 | 100 | |

| G.Total area | M2 | 1700 | |

| pratical workers arrangement | |||

| control/operation | 1 | wheel loader | 1 |

| forlift | 2 | repaire/maintain | 1 |

| sum | 5 | ||

2. QT4-15B Automatic block forming machine Production capacity:

| Size(LxWxH) | Pcs/Mould | Pcs/ Hr | Pcs/ 8 Hr | m3/year |

| 400X100X200 | 8 | 1200-1920 | 9600-15360 | 27648-36864 |

| 400X150X200 | 6 | 900-1440 | 7200-11520 | 31104-41472 |

| 400X200X200 | 4 | 600-960 | 4800-7680 | 27648-36864 |

| 400X250X200 | 3 | 450-720 | 3600-5760 | 25920-34560 |

| 200X100X60 | 16 | 1920 | 15360 | - |

| 200X163X60 | 8 | 1200 | 9600 | - |

| Can make all kind of hollow and solid and paver block | ||||

3. How does Automatic Block Making Machine work?

1. Screw Conveyer (Optional fitment): loading bins of the instrument for transporting Fly Ash from the silos(optional fitting) or cement hopper (optional fitting) to the Batching Plant.

2. Batching Plant: It consists of three loading bins and one weighing bin. It also contains blet conveyers to convey materials from loading bins to weighing bin. Batching and weighing is done by PLC control. We can load three different types of material into the loading bin.

3. Conveyer Belt: When the Batching plant's weighing bin trips according to the PLC control, the material comes to this conveyer belt. Then conveyer belt carried materials to the Mixture Machine.

4. Concrete Mixture Machine: All the ingredients are mixed in this mixture machine. Mixing time and speed is controlled by PLC. The inbuilt water pump adds water to the mixer automatically, as per requirement.

5. Block mold machine: This is key of the production line. It can press the mixed material. So it can make various hollow block, solid brick, paver brick and kerbstone.

6. Stacker: Stacker is used to lay the block automatically, which is high-efficient and labor saving.

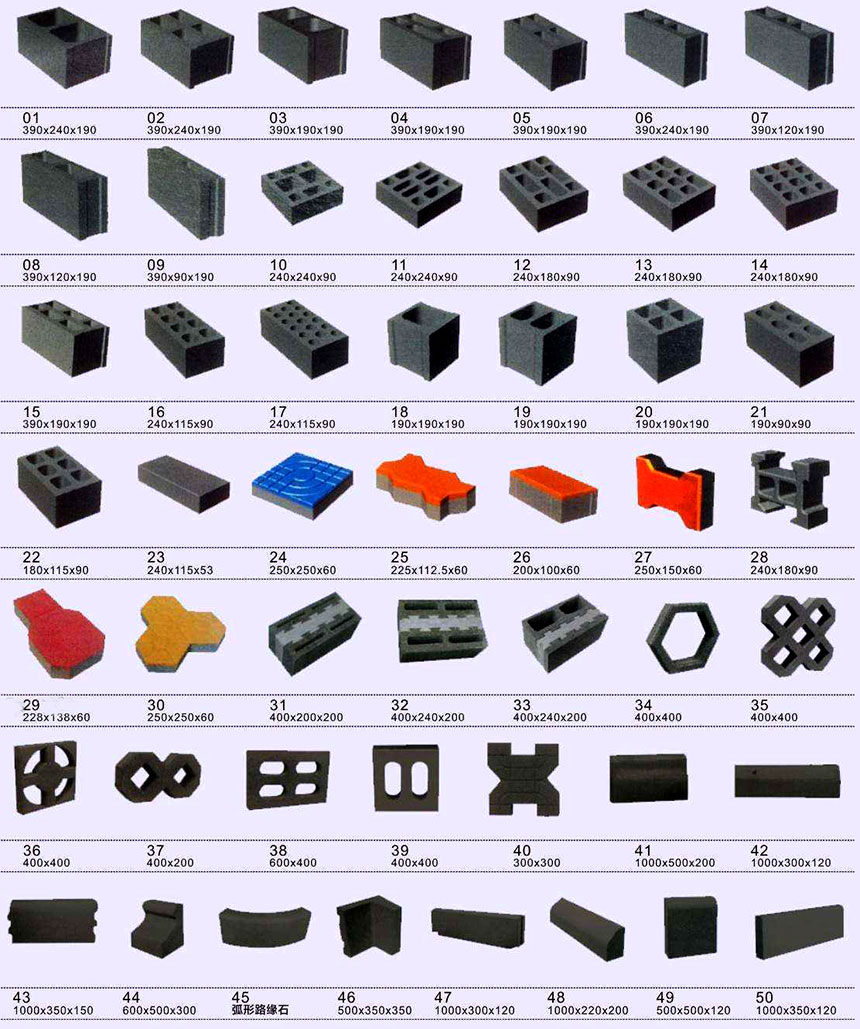

4. Block and Brick Models:

Technical support and after-sales service team in the Philippines

1. 24 hours online service freely;

2. One year warranty time except for vulnerable parts.

3. Life long maintenance service;

4. Send engineers to install and debug the equipment;

5. Freely train operators to use and maintain skills;

6. Send engineers to fix failure if customers need;

7. Supply all kinds of spare parts;